How is Concrete Made

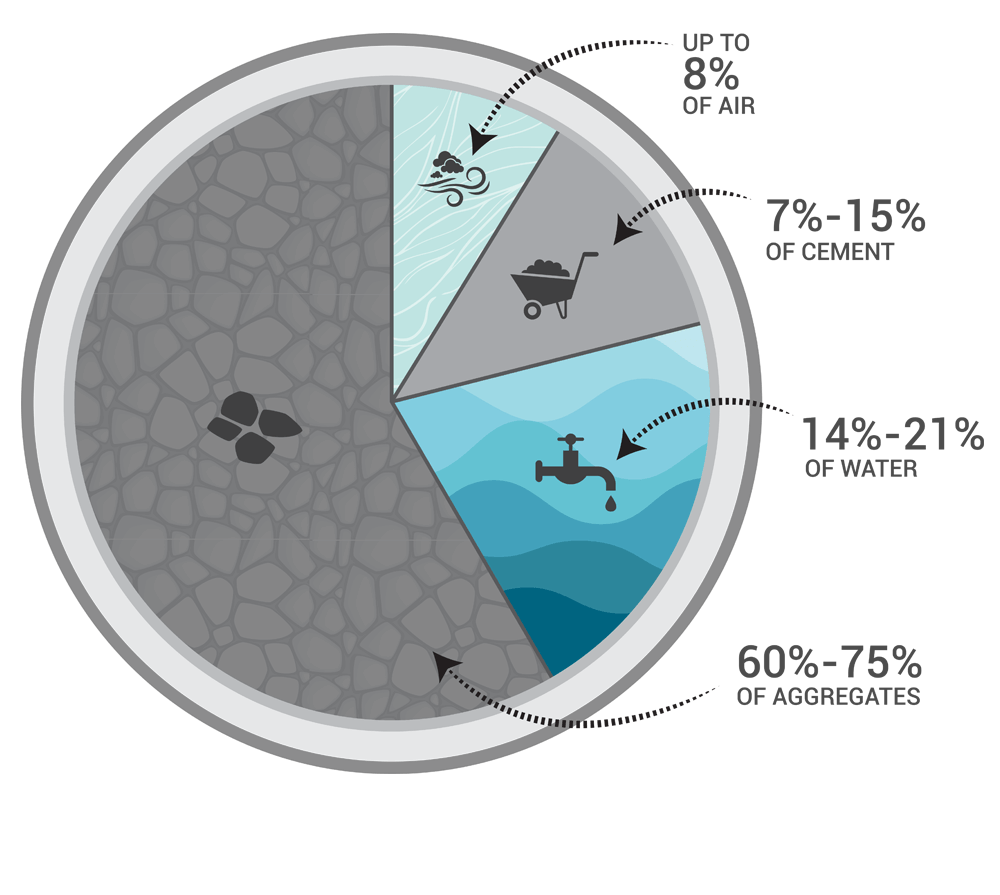

Concrete is a mixture of two components: aggregate (coarse & fine) and paste. The paste is made up of cement and water. Through a process called hydration, the cement and water harden and bind the aggregates; sand, gravel or crushed stone, into a rocklike mass which is known as Concrete. This hardening process continues for years meaning that concrete gets stronger as it gets older.

Concrete has an incredibly high compressive strength. Measured in pounds-per-square-inch (psi) compressive strength refers to the amount of force needed to break a material.

Today, concrete is the world’s most-popular man-made building material, used to build everything from superhighways to kitchen countertops. More than 7 billion cubic meters of concrete are produced each year. That’s one cubic meter for every person on the planet!

Versatility OF Concrete

Concrete is virtually fire-proof. It doesn’t burn, it can’t be set on fire, and it doesn’t release toxic fumes when it comes into contact with flames. And thanks to the slow rate of thermal conductivity of concrete – or heat transfer – concrete is an effective fire shield. That’s why buildings and other structures made from concrete are able to survive a fire when everything around goes up in flames.

Concrete is also naturally water resistant. The use of membranes and special concrete mixes can make it virtually waterproof, making concrete the ideal building material for underground structures like lower levels, basements, and parking structures.

The fact that concrete can withstand water with ease has made it a popular choice for garden décor and outdoor furniture. But concrete can be used to beautify the inside of the home, too. Concrete’s incredible versatility and durability makes it the perfect building material for custom countertops, sinks, and fireplaces. And concrete floors can be a surprisingly economical way to give any indoor living space a sleek, contemporary look that’s low-maintenance and that will take a lifetime of wear and tear.

Reinforced Concrete

A composite material, obtained by adding steel meshes or rods or other elastic materials to the concrete. This is an extremely strong material, and due to its capacity to resist different types of stress it plays a key role in the construction of buildings. Another factor behind the successful combination of these two materials – concrete and steel – is, their almost identical thermal expansion coefficients. As a result, when a reinforced concrete component undergoes a drastic change of temperature, there are no warping or cracks. Concrete also protects the steel against corrosion. All around the world reinforced concrete is the main building material for residential, commercial and industrial buildings.

Reinforced Concrete is water resistant: While it is not technically water resistant by default, the versatility of the concrete lies in the fact that it is a mixture of components, and a little tweak in the aggregate mixes can bring out the water-resistant qualities of the concrete, making it perfect for underwater structures.

So, it comes as no surprise that Concrete; being a building material second to none in terms of convenience, speed of application and strength, is used more than any other manmade material on the planet!

What is Ready mix Concrete(RMC)

Ready Mix Concrete is concrete that is manufactured in a batching plant, according to a set ratio (called a Mix Design), and then delivered to your work site in trucks, mounted with in–transit mixers.

Ready Mix Concrete is,

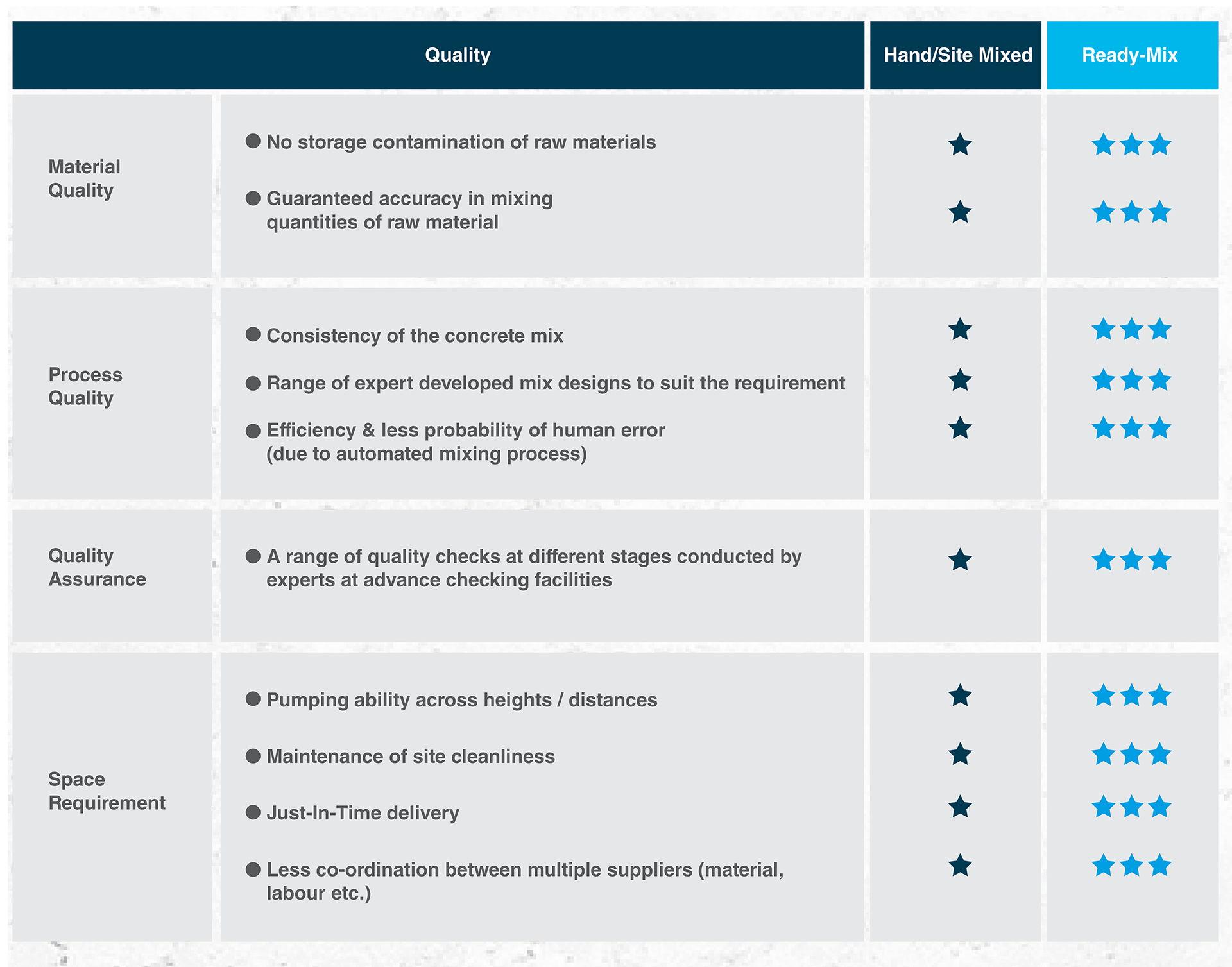

- Superior in Quality

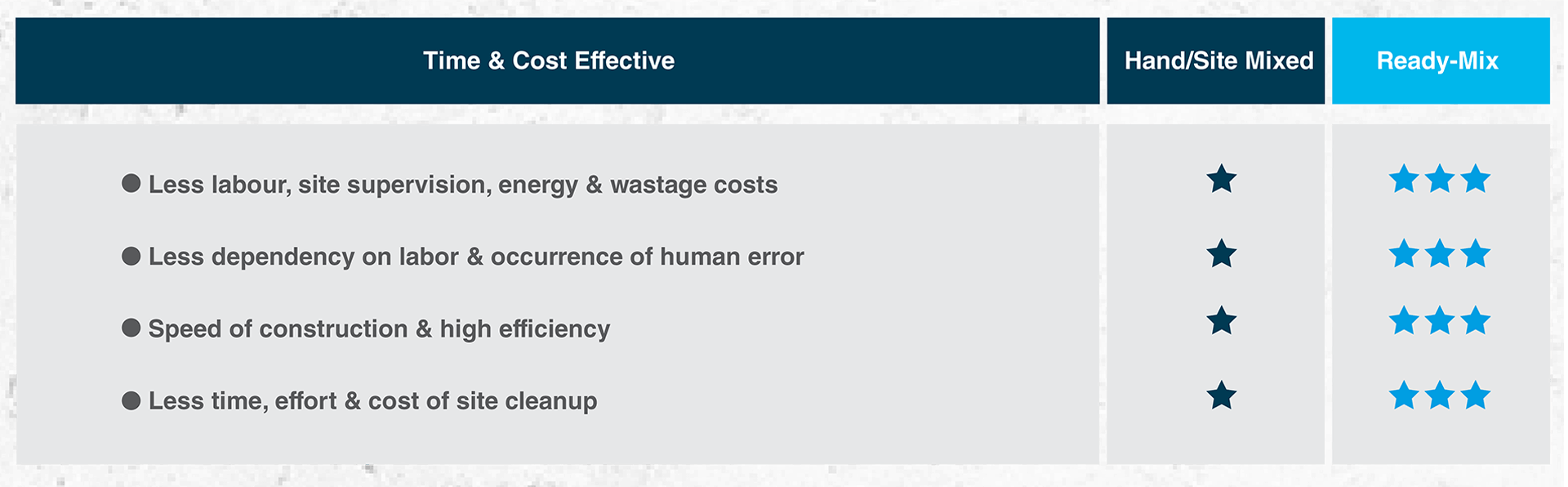

- Time & Cost Effective

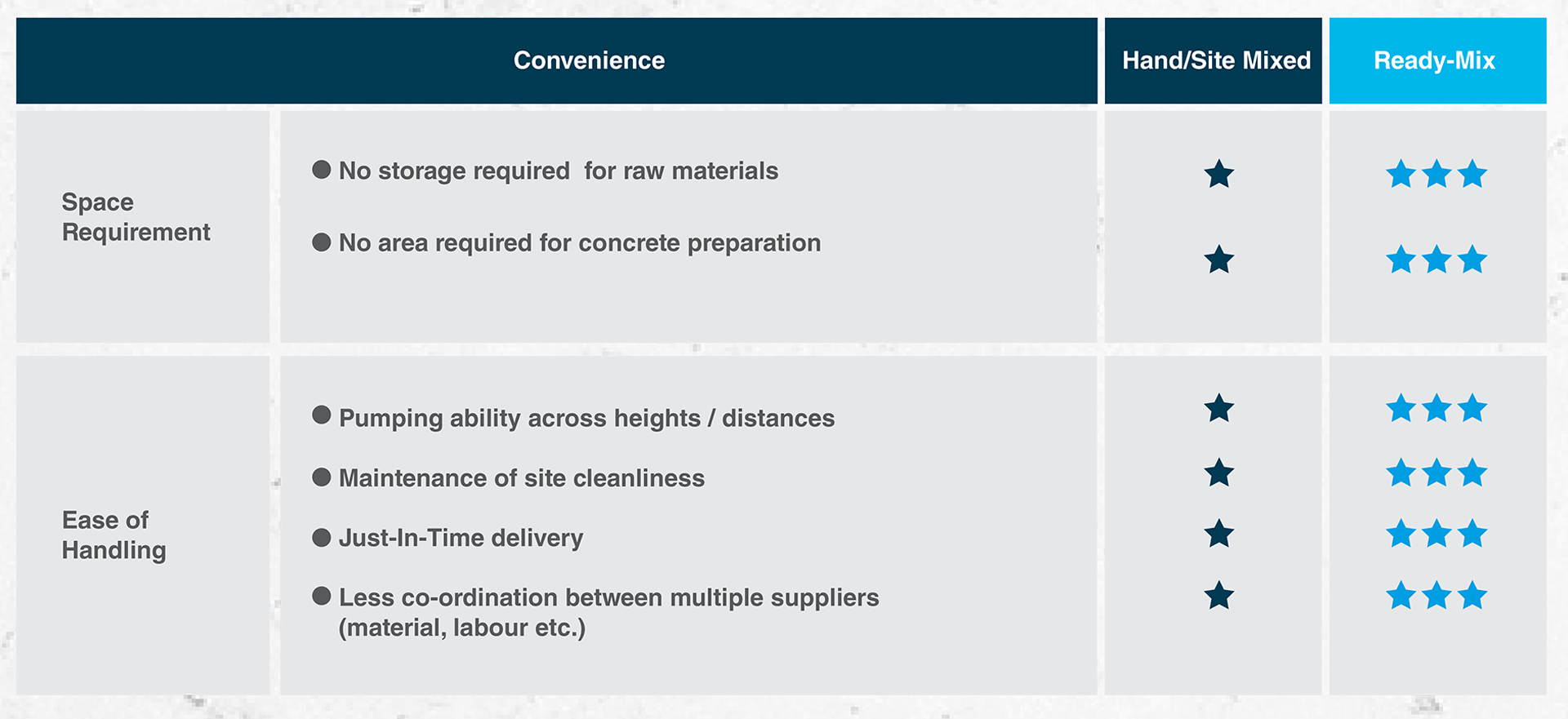

- Convenient, and

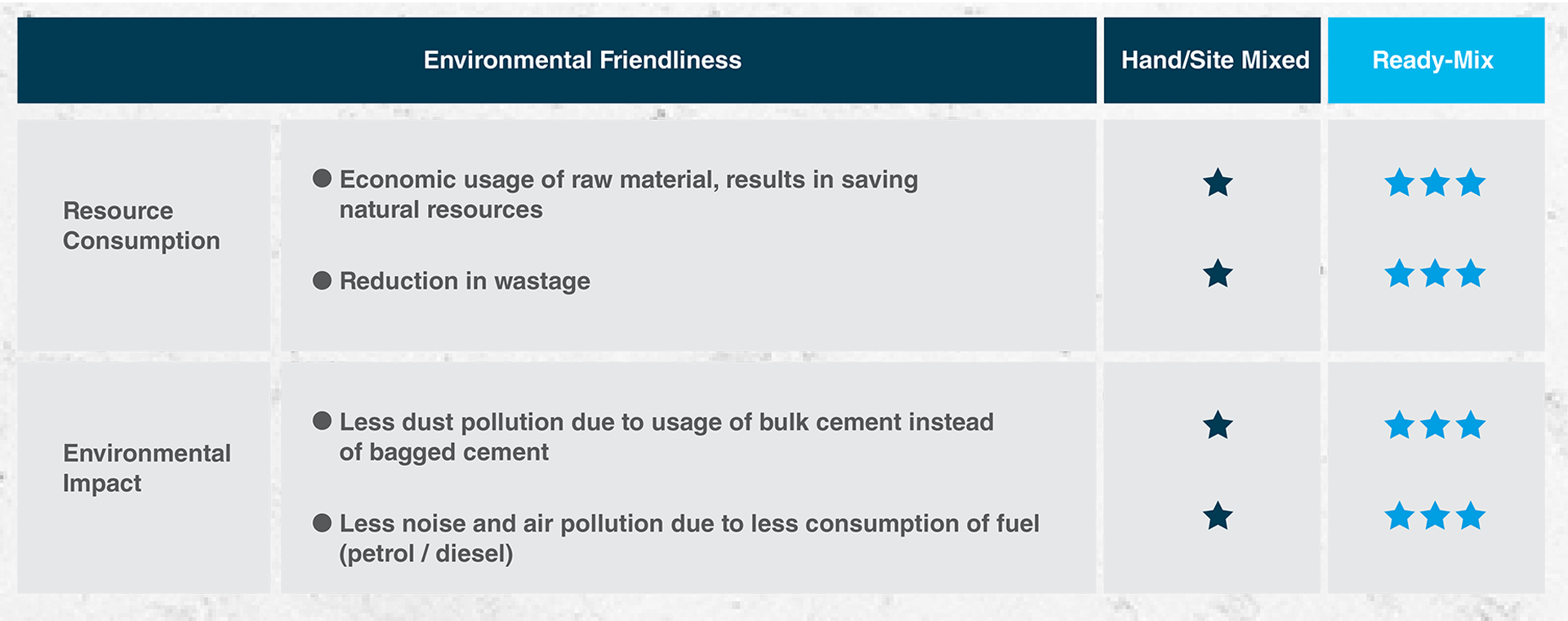

- more Environment-friendly.

Ready Mix Concrete accounts for nearly three-fourths of all concrete used annually around the world. Mixing concrete has traditionally been a laborious task. Until the invention of the Concrete Mixer this job was usually carried out using a shovel, spade or other implement to mix in a wheelbarrow or other container, so a Concrete Mixer can save a great deal of time and effort.

Due to a number of benefits compared to conventional methods used to make concrete (Hand Mixed & Site-mixed Concrete), today Ready Mix Concrete is widely preferred, specially by construction industry experts and even home builders.

Recommended Usage

Instructional Video

Curing Concrete

Curing of concrete is to provide adequate moisture, temperature, and time to allow the concrete to achieve the desired properties for its intended use. This plays an important role on strength development and durability of your concrete. When concrete is not cured properly, its durability, strength can be affected resulting complications such as cracks, leaks, honeycombing and even collapses.