Tokyo Super 2K-waterproofing coating is a two component, cementitious and acrylic waterproofing slurry which is consisting with ordinary Portland cement, graded aggregate and organic additives. This product can be used for concrete and mortar structures to prevent the water ingress.

Recommended Usage

Application Method

Mixing

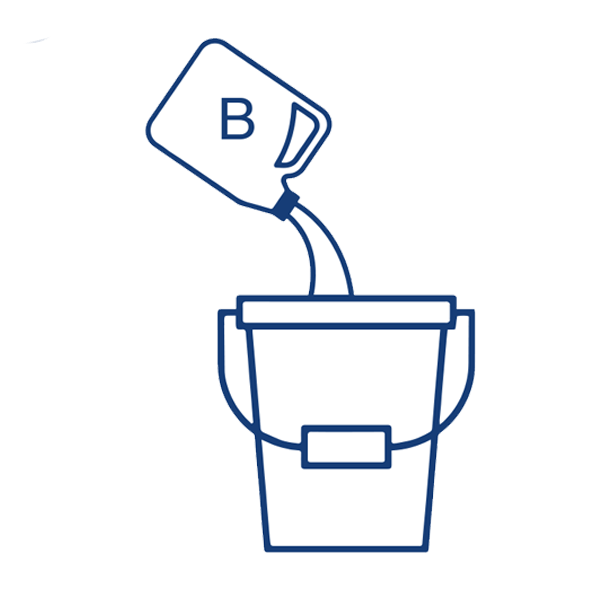

Shake component B (liquid) well before mixing.

Pour component B (1kg liquid) completely into a mixing bucket.

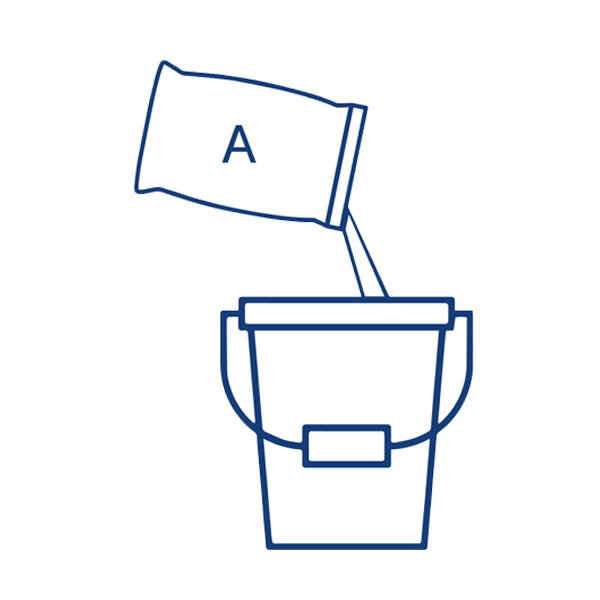

Slowly add the component A (2kg powder) into the bucket while mixing.

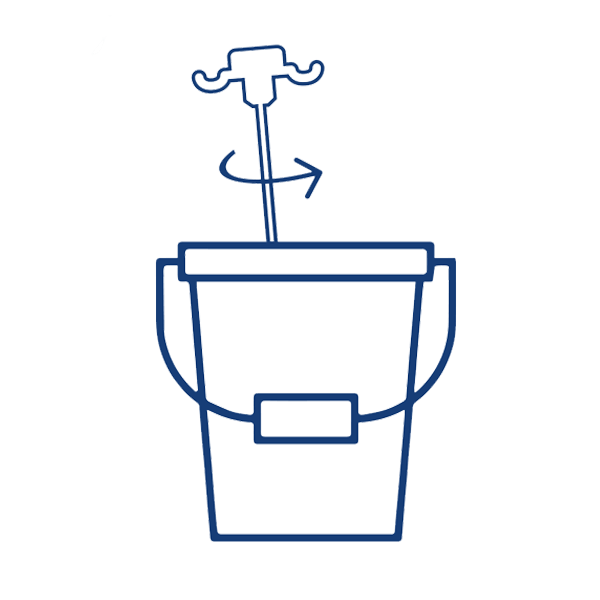

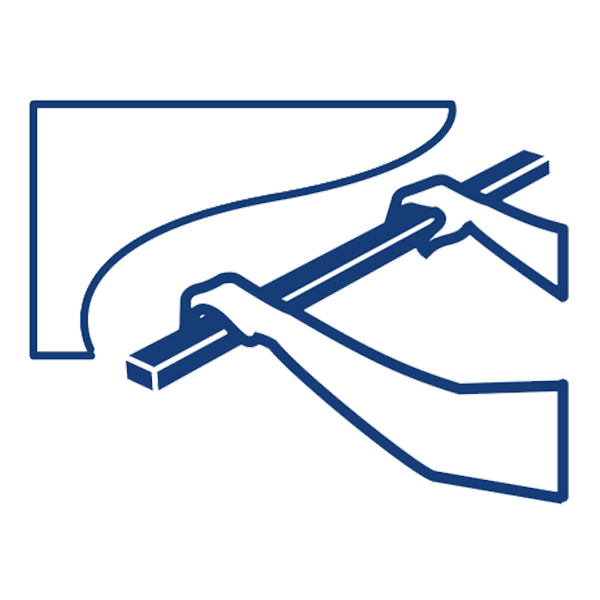

Continue mixing using low speed mechanical mixer (300-400 rpm) for 3 – 5 minutes to a homogeneous slurry.

Application

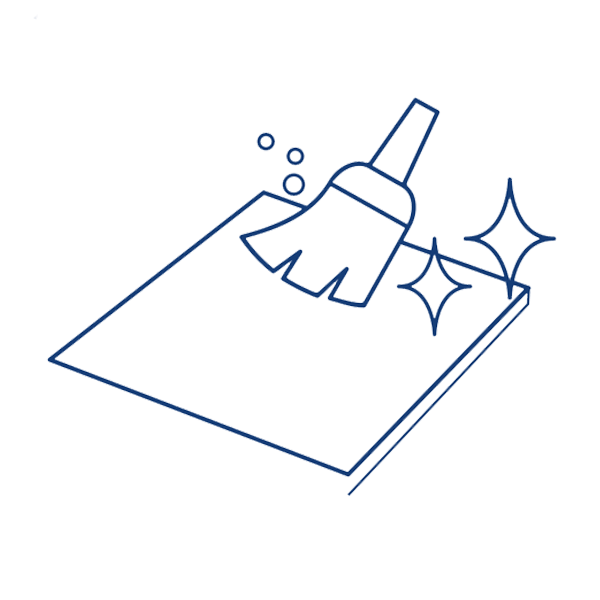

Clean and remove all loose materials, oil, grease and other impurities. Thoroughly wire brush the surface and remove the dust by vacuum cleaner.

The area to be waterproofed should be washed with clean water and prior to applying, remove all standing water.

Masonry float or brush can be used for the applying of Tokyo Super 2K-waterproofing coating.

Apply the first coat (approx. 0.8mm – 1mm) in a vertical direction to cover the whole area.

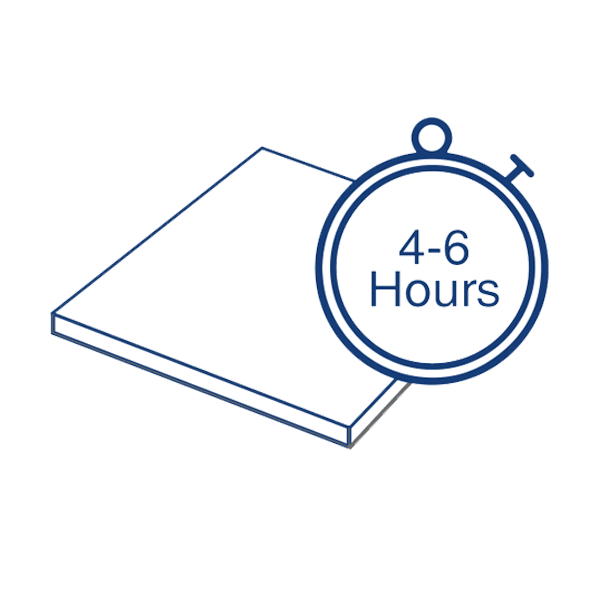

Let the first coat dry for 4 – 6 hours.

Apply the second coat (approx. 0.8mm – 1mm) in a horizontal direction.

Protect the applied area from direct sunlight and wind to prevent the plastic shrinkage due to loss of moisture.

Air curing is sufficient.

Tiles can be fixed on Tokyo Superseal 2K waterproofing applied surface after 7 days.

Other Notes

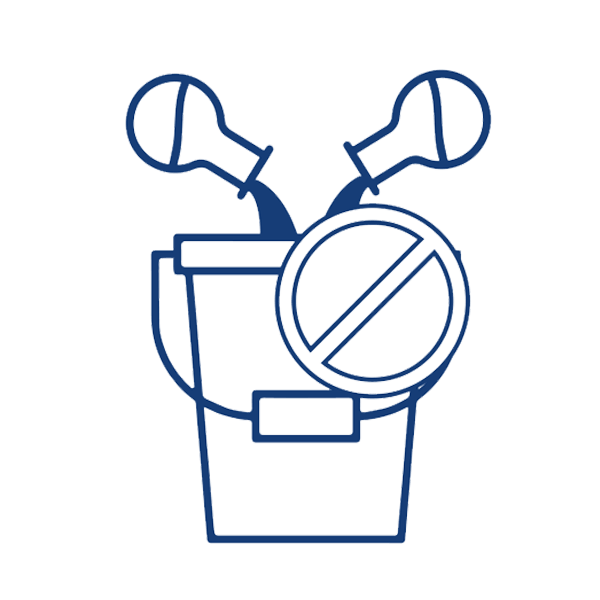

Do not add the cement or other cementitious material.

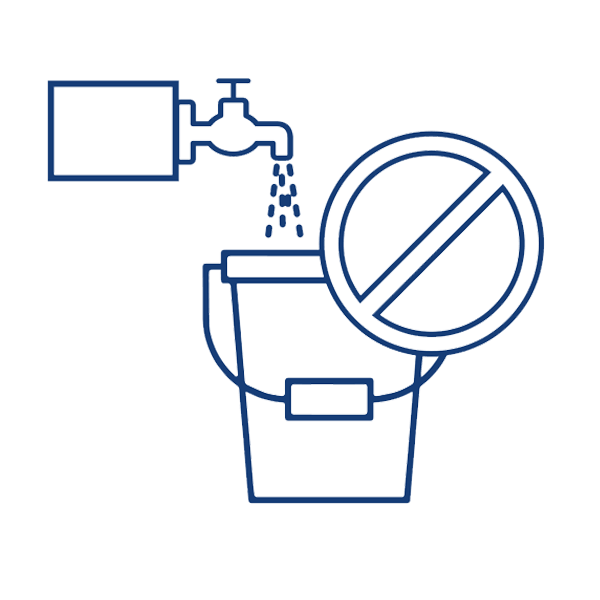

Do not add additional water to slurry.

Do not add plasticizers, retarders, accelerates and other additives.

Apply a protective screed/mortar layer on the waterproofed area for protection.