TOKYO SUPERMIX offers a range of mix-designs to satisfy varying customer requirements in a vast range of applications from high rise buildings, water projects, highways and bridges to decorative concrete for commercial and residential buildings.

TOKYO SUPERMIX is proud to be the trusted choice of leading construction firms and building consultants, not only for local projects but also for multinational collaborations that are redefining the country’s landscape. On many fronts, we have been the only supplier who was able to meet some of the stringent guidelines set by the international developers behind some of the iconic projects currently being implemented.

Normal Pumpable Concrete

A hassle-free, versatile solution used for multiple concreting requirements in various parts of a construction, ranging from casting of structural elements to finishing floors and bathrooms. Recommended for small sized commercial buildings, houses, culverts, factory floors and lower levels of taller buildings, normal pumpable concrete is available in strength grades C15 to C45, with 20 -150mm slump and can be pumped up to about 5 floors of a building.

| Project | Residential Projects and Commercial Buildings | |

|---|---|---|

| Challenge |

The customer wanted a hassle-free, versatile solution that can be used for multiple

concreting requirements in various parts of the house which included the casting of

structural elements as well as finishing floors and bathrooms.

|

|

| Features |

Perfect for casting typical structural elements such as slabs and columns. Strength

grades C15 to C45, with 20 -150mm slump falls within this category of concrete which

can be pumped up to about 5 floors of a building.

|

|

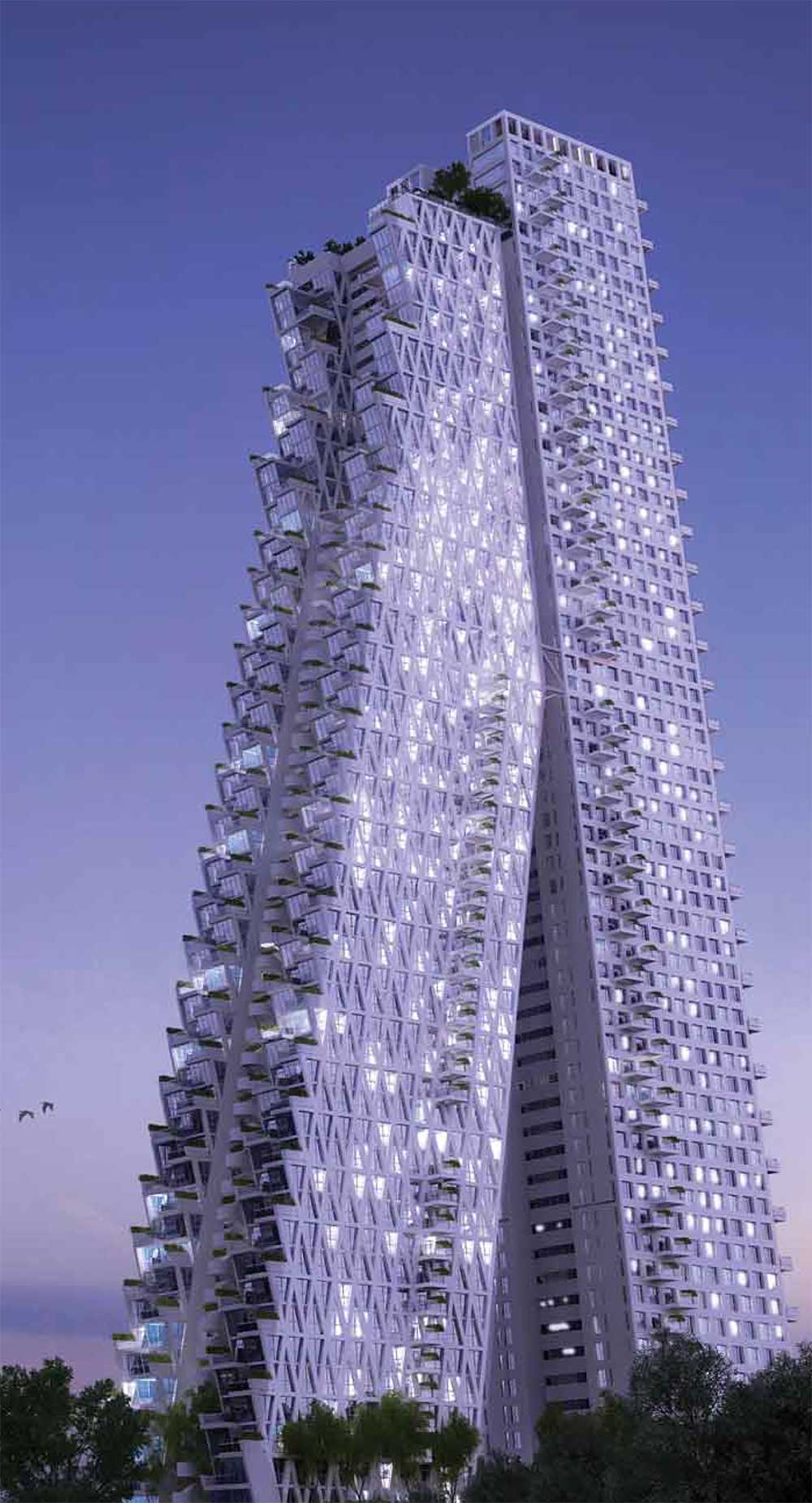

High Flow Concrete

A design specially formulated to deliver enhanced flowability with minimum segregation, making it easier to pump concrete to heights exceeding 150m and flows easily through reinforcement bar matrix.

| Project | Altair | |

|---|---|---|

| Challenge |

Pumping concrete to high-rises require extra flowability. Therefore, the solution must carry the right blend of cementitious materials and admixtures to enable easy pumping to great heights using stationary pumps. |

|

| Features |

This design is specially formulated to deliver enhanced flowability with minimum

segregation, which makes it easier to pump concrete to heights exceeding 150m and

flows easily through reinforcement bar matrix. Rheology characteristics are Slump

225mm and Slump Flow 450-600mm.

|

|

Piling Concrete

This formula is especially designed with a slump of 180mm – 220 mm making it ideally suited for in-situ bored piles, that are usually fed through ‘trimy pipes’ requiring extra-high flowability.

| Project | Havelock City | |

|---|---|---|

| Challenge |

One of the main requirements for piling work is smooth flowability, which allows the concrete to reach every corner of the bore hole, usually fixed with a steel reinforcement cage. Since piling takes a longer duration, maintaining a homogeneous mix design through the entirety of the piling phase is very important. |

|

| Features |

This formula is especially designed with a slump of 180mm – 220 mm making it ideally

suited for in-situ bored piles, that are usually fed through ‘trimy pipes’ requiring

extra-high flowability. Critical fresh state properties such as homogeneous mix

without segregation and the first truck’s slump retention up to reaching of the last

truck to site are achieved by using proper aggregates and admixtures.

|

|

Ultra-High Strength Concrete

In high rise buildings, columns at the bottom most levels can become significantly large due to the weight of the total structure. But necessity to maximize space and improve visual appeal demands the reduction of column sizes, thus calling for high-performance concrete that is robust yet versatile. This demand can only be met by ultra-high strength grades such as C70 and C85.

| Project | Keells City - Cinnamon Life | |

|---|---|---|

| Challenge |

In high rise buildings, columns at the bottom most levels become significantly large

due to the weight of the total structure they have to bear. This impedes space

availability in lower levels, mostly used as parking bays or as prime commercial

space.

|

|

| Features |

To date TOKYO SUPERMIX is the only concrete in Sri Lanka to achieve both strength grades C70 and C85, and was the winning criteria in becoming the only approved supplier to this landmark project. The superior strength gaining characteristics of NIPPON CEMENT PRO OPC Cement is the main contributory factor along with other constituent materials in the design such as the water reducing Poly Carboxylic Ether type admixture. The modern testing machines for such grades are available only with TOKYO SUPERMIX labs and a few other places, attesting our ability to meet a very specific niche in demand. |

|

High Early Strength Concrete

This special mix design garners early strength and enables the post-tensioning process, early removal of form work, intermittent shifting of formwork etc. as the case may be.

| Project | Orion City PT Slabs | |

|---|---|---|

| Challenge |

Post tensioning of slabs, precast girders, slip-form construction and in-situ bridge girder constructions requires early strength gaining property |

|

| Features |

This special mix design garners early strength and enables

the

post-tensioning

process, early removal of form work, intermittent shifting

of

formwork etc. as the

case may be.

|

|

Durable Concrete

Durable concrete conforms to requirements like sulphate and chloride nce and low water absorption etc., and is normally prescribed for harsh environments such as marshy or marine by the consultants.

| Project | ITC Hotel | |

|---|---|---|

| Challenge |

Durable concretes have become an integral part of structures coming up along the Colombo coast line and Colombo city in general. Durable concrete conforms to requirements like sulphate and chloride resistance and low water absorption etc., and is normally prescribed for harsh environments such as marshy or marine by the consultants |

|

| Features |

The chemical and water resistance in durable concrete comes from

using

TOKYO SUPER PLUS or Fly Ash blending amongst the use of other

ingredients

such as silica fume and slag (GGBS) in the special mix designs.

These

designs

give a denser closely packed concrete structure resistant to

chloride

penetration and sulphate attack.

|

|

Light Weight Concrete

Typically used to fill voids in the structures to raise floor levels to achieve functional requirements or to maintain unique aesthetic value without the burden of added weight especially in mixed-development sites such as hotels and condominiums. The unique foam blending technique used to achieve a very low density (600 - 1200 Kg/m3), so far is mastered locally only by TOKYO SUPERMIX.

| Project | Shangri La Hotel & Shangri La Towers by China Harbor | |

|---|---|---|

| Challenge |

These specific projects sought to maintain high and/or unique aesthetic value and had inbuilt special architectural features, which required additions be made to the basic structure without the burden of added weight. Especially in mixed-development sites such as hotels and condominiums that include kitchens and swimming pools located on higher floors, special structural adjustments that are versatile and lighter are required. |

|

| Features |

Light weight concrete is typically used to fill voids in the structures that needs filling-up to raise floor levels to achieve functional requirements. The unique technique used to achieve very low density (600 – 1200 Kg/m3 ) is so far mastered only by TOKYO SUPERMIX. The proprietary foam blending technology and the process followed enables this achievement |

|

Temperature controlled concrete

In structural elements such as thick raft foundations and large-sized columns/beams temperature of the "core" needs to be maintained below 72-75°C depending on the consultant discretion. Formulation of low temperature concrete needs total temperature control of all ingredients, a range of specific ancillary equipment such as high capacity water chillers, ice crushing machines, freezer containers and scientific expertise and technological insights to use the right mix of cementitious materials and admixtures in achieving this precision-driven solution mix. Equipped with state-of-the-art machinery and batching plants, TOKYO SUPERMIX has achieved temperatures as low as 26 °C

| Project | Spathodea Residencies | |

|---|---|---|

| Challenge |

In structural elements such as thick raft foundations and large-sized columns, temperature of the ‘core’ or center need to be maintained below 72oC - 75oC depending on the consultant discretion. |

|

| Features |

Formulation of low temperature concrete needs total temperature

control of

all ingredients such as fine aggregate, coarse aggregate, water and

cement.

Such mix designs require scientific expertise and technological

insights to

use the right mix of cementitious materials and admixtures, along

with the

mechanics to maintain ingredient temperature control.

|

|

Freeze-Thaw Resistant Concrete

A special mix design with the ability to prevent concrete from cracking due to fluctuating temperatures (I.e. cold storage facility). Fly Ash blending and use of other special ingredients enables to meet varying demands of frozen and thawed cycles, and withstand sudden expansion or shrinkage due to water freezing.

| Project | Cold Store Complex of CIC – Pannala | |

|---|---|---|

| Challenge |

A key structural requirement in this context was the ability to prevent the concrete from cracking due to fluctuating extreme temperatures that occur inside a typical cold storage facility. |

|

| Features |

Fly Ash blending and use of other special ingredients enabled creating a special concrete mix to meet varying demands of frozen and thawed cycles, and withstand sudden expansion and shrinkage resulting from water freezing. |

|

Non-Shrink Concrete

A concrete design with special properties which allow better bonding to avoid air traps. Seamless super-flat floors need minimization of shrinkage to avoid crack formation. Therefore concrete is mixed with steel fiber reinforcement as steel bar reinforcement usage can give rise to crack formation.

| Project | DSI Warehouse – Weligama | |

|---|---|---|

| Challenge |

Seamless super-flat floors need minimization of shrinkage to avoid crack formation. |

|

| Features |

This mix design done with carefully selected materials and appropriate admixtures result in special properties which allow better bonding of the concrete to avoid air traps. The concrete is mixed with steel fiber reinforcement since steel bar reinforcement usage can give rise to crack formation |

|

Self-Compacting Concrete

A free-flowing concrete that flows though the spaces in the rebarmatrix and fills up the form work without segregation eliminating the need for poker vibrating, whilst achieving a honeycomb free structure. This also helps to avoid high dependency on labour and reduces time taken for manual compacting of floors and slabs.

| Project | Avic Astoria | |

|---|---|---|

| Challenge |

The matrix of reinforcement steel bars in certain structural elements necessitates extra poking of concrete during placing, which is a time and labour intensive process making a significant impact on the overall project efficiency. |

|

| Features |

Self-compacting concrete, formulated using a different combination of coarse aggregates and appropriate admixtures, helps avoid high dependency on labour and reduces time taken for manual compacting of floors and slabs. This free-flowing concrete flows though the spaces in the rebar-matrix and fills up the form work without segregation. This eliminates the need for poker vibrating, whilst achieving a honeycomb free structure. Fresh state workability is measured in terms of filling ability and passing ability using V-Funnel/Slump Flow and J-Ring/L-Box apparatus respectively. Segregation resistance is also another check carried out visually during above tests. |

|

Exposed Concrete with Corrosion Inhibitors

The special corrosion inhibitors are added to the durable concrete design in order to improve corrosion resistance of the construction significantly in order to maintain longevity of the structure.

| Project | New US Embassy Building Complex – Colombo | |

|---|---|---|

| Challenge |

The new multi-building office complex commissioned by the US

Government

required compliance to stringent quality standards with specific

compliance

to US regulatory requirements in engineering, sustainability and

construction

execution. The project is registered with the U.S. Green Building

Council

for

Leadership in Energy and Environmental Design (LEED®) green building

rating system and is projected to earn LEED® Silver status.

|

|

| Features |

Manufactured Sand and Blended Cement based mix design uses a PCE admixture. Quality assured M-Sand from Tokyo Super Aggregate was used to maintain material consistency. The application was carried out during night hours to maintain fresh state properties very close to specified levels. |

|

Water Proof Concrete

A hydrophobic ingredient is added to the blended cementitious materials to arrive at a design that maintains a very low water-cement ratio. This produces a dense and low water permeable concrete, typically used for below ground level structures and water tanks.

| Project | Eli House Water Tank – Modara | |

|---|---|---|

| Challenge |

Water proofing the structure is one of the most common requirements in any building. This need becomes a high priority for water tanks, swimming pools and basements. |

|

| Features |

A hydrophobic ingredient is added to the blended cementitious materials to arrive at a design that maintains a very low water-cement ratio. This produces a dense and low water permeable concrete, typically used for below ground level structures and water tanks. |

|

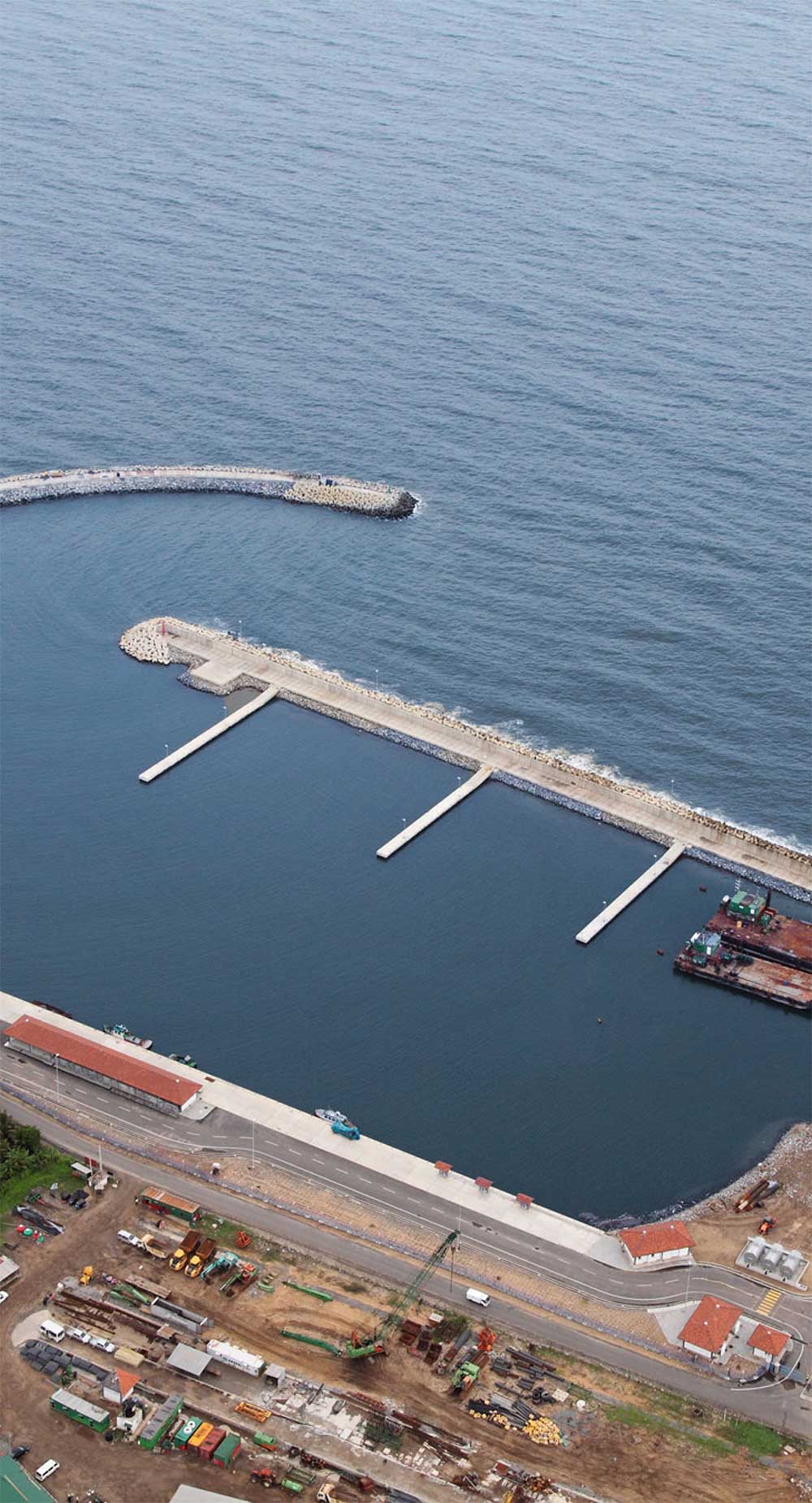

Underwater Concrete

A Special concrete solution, placed usually through a steel casing, is enriched with a viscosity modifying agents which gives the concrete anti-washout properties.

| Project | Fisheries Harbor – Dikowita | |

|---|---|---|

| Challenge |

For underwater constructions, the main challenge is to prevent cement and fine particles getting washed off when water comes into contact with fresh concrete during concrete pouring process. This requires a higher level of bonding with chemical features that can withstand various water salinity levels. |

|

| Features |

The concrete solution, placed usually through a steel casing, is enriched with a viscosity modifying agent which gives anti-washout properties. |

|

Colour Concrete

Leaching free colour concrete is done by adding the correct combination of cementitious materials, admixtures & colour pigments to the concrete. Later the surface is cut and polished using diamond cutting wheels resulting a maintenance free floor finish that does not need waxing or sealant application.

| Project | HNB Bank – Nittambuwa | |

|---|---|---|

| Challenge |

Adopting a decorative and colourful concrete finish, for the interior design of contemporary offices or living spaces of commercial and residential buildings is a trend. Maintenance free architectural colour finish floors can be done when slabs are poured with colour concrete. |

|

| Features |

Colour pigment is added to the concrete and later the surface is cut and polished using diamond cutting wheels. The resulting floor finish hence does not need waxing or sealant application. It is a maintenance free floor that needs only mopping with water. Leaching free colour concrete design is done using the correct combination of cementitious materials and admixtures / colour pigments. The aggregate used by TOKYO SUPERMIX is clean and devoid of any foreign matter. Hence, an unblemished finish is obtained, when cut and polished using the right equipment |

|

Fair Finish Concrete

A special mix that has high flowability and exact quantities of fine particles enabling a durable and maintenance free smooth finish.

| Project | Toll Gates of Southern Expressway – Kurundugaha-Hathakma | |

|---|---|---|

| Challenge |

This exposed concrete required a smooth, seamless finish after the specially designed formwork is removed, while being durable and maintenance free. |

|

| Features |

High durability and maintenance free smooth finish are hallmarks of this particular formulation of concrete. A special mix that has high flowability and exact quantities of fine particles enables this surface finish. A superior rheology is maintained in this segregation and bleeding through controlled high slump concrete. |

|

Decorative Architectural Concrete

Decorative Concrete without any further finishing requires a high degree of uniformity in color and overall appearance. The latex formwork boards used generates a "wood grain" finish on the concrete surface. Manufactured Sand and Blended Cement based mix design uses a PCE admixture.

| Project | New US Embassy Building Complex - Colombo | |

|---|---|---|

| Challenge |

Decorative Concrete without any further finishing requires a high degree of uniformity in color and overall appearance. The latex form work boards used generates a "wood grain" finish on the concrete surface. The contractor adheres to a strict cleaning procedure on latex mould lined form work boards to ensure consistency of the physical implements used for the project. Our challenge was to provide consistent color and texture of final architectural finish of the concrete. |

|

| Features |

This innovative zero slump concrete design enables water draining

into soil

through the structural porosity of concrete in applications such as

car

parks,

walkways, pavements etc

|

|

Flowable / Pumpable Screed Mortar

Unwashed Manufactured Sand with more fine particles and Blended Cement based mix design uses a PCE admixture. This combination creates the necessary pumpabilty and flowability required in this application. Flowability enables masons to lay it several times faster using longer leveling bars with the aid of pre-set levels covering larger areas in different floors of multistoried buildings.

| Project |

Cinnamon Life Project Colombo Technical Building Project – Tokyo Cement Trincomalee |

|

|---|---|---|

| Challenge |

Due to the scarcity / high cost of river sand and to enable fast construction an alternative to ‘manual cement rendering’ on floors was required. The skilled mason availability has also become a problem to do such finishes fast presently in projects |

|

| Features |

Unwashed Manufactured Sand with more fine particles and Blended Cement based mix design uses a PCE admixture. This combination creates the necessary pumpabilty and flowability required in this application. Flowability enables masons to lay it several times faster using longer leveling bars with the aid of pre-set levels covering larger areas in different floors of multistoried buildings. |

|

Expansive or Shrinkage Compensating Concrete

A shrinkage-reducing, high-performance expansive additive is used in concrete to generate the required expansion from within the concrete to compensate for the general shrinkage taking place during concrete hardening. Thus the possibilities of micro-cracks / capilary formation is eliminated and water tightness is improved to ensure 100 years lifetime.

| Project | Highway sections from new Kelani bridge (NKB) to Ingurukade and Orugodawatta junctions | |

|---|---|---|

| Challenge |

The Highway Sections from NKB to Ingurukade Junction and

Orugodawatta Junction are

constructed on a steel structure. The top deck is rested on

support

columns on either

side. The deck bottom steel corrugated plate is covered with

concrete and subsequently

waterproofed before finishing with an asphalt layer. The

road is

given a 100 years lifetime

by design. Hence ‘water’ and ‘air’ penetration from possible

micro

cracks / capillaries on

the top deck concrete

|

|

| Features |

A shrinkage-reducing, high-performance expansive additive is used in concrete to generate the required expansion from within the concrete to compensate for the general shrinkage taking place during concrete hardening. Thus the possibilities of micro-cracks / capillary formation is eliminated and ‘water tightness’ is improved to ensure 100 years lifetime. |

|

Shotcrete Concrete

A cost effective thin concrete layer is achieved by using Only 0-5 mm fine aggregates and 5-14 mm chips. The mix is sprayed on to surfaces needed stabilizing or improvement using a special pumping machine with a chemical accelerator. This accelerator is simultaneously fed with the concrete mix setting in quick hardening.

| Project |

Altair New US Embassy Project |

|

|---|---|---|

| Challenge |

Soil stabilizing in excavated basements was required in the US Embassy project site. Altair project needed corrections on some peripheral piles. A cost effective thin concrete layer was the required product in such situations. |

|

| Features |

A concrete made with only fine 0-5 mm fine aggregates and 5-14 mm chips are used in Shotcrete Concrete. The mix is sprayed on to surfaces needed stabilizing or improvement using a special pumping machine with a chemical accelerator. This accelerator is simultaneously fed with the concrete mix setting in quick hardening. |

|